Industrial metal keypads play a vital role in ensuring seamless operations in industrial environments. You rely on their durability and precision to handle demanding tasks. Recent advancements in industrial metal keypad design and functionality review reveal innovations that enhance performance. Evaluating these keypads for usability and resilience ensures they meet your operational needs.

Key Takeaways

- Pick metal keypads made of strong materials like stainless steel. They last long and work well in tough places.

- Check for keypads with high IP ratings, like IP65 or more. This keeps them safe from dust and water.

- Think about features you can change, like button layouts and lights. These make the keypad easier to use and fit your needs.

Design and Build Quality

Material Composition and Durability

When evaluating industrial metal keypads, you should prioritize their material composition. These keypads are typically made from stainless steel or other durable metals. This choice of material ensures resistance to corrosion caused by saltwater or humidity, making them ideal for long-term use in challenging environments like marine applications. Their robust construction allows them to endure heavy use and environmental damage, reducing maintenance and replacement costs over time.

Key features that enhance durability include:

- Heavy-duty materials capable of withstanding extreme temperatures and vibrations.

- Wear-resistant keys designed to prevent accidental presses and ensure reliability.

- High Ingress Protection (IP) ratings, such as IP65 or higher, which indicate resistance to dust and water.

These qualities make industrial metal keypads a reliable choice for demanding industrial settings.

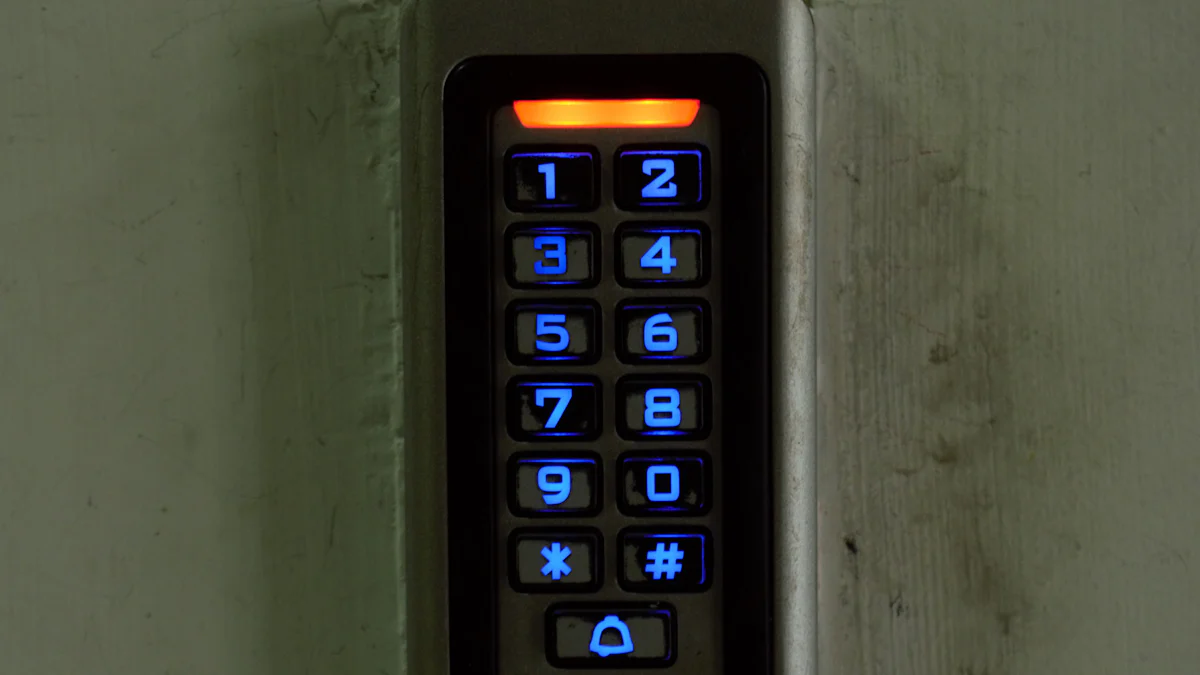

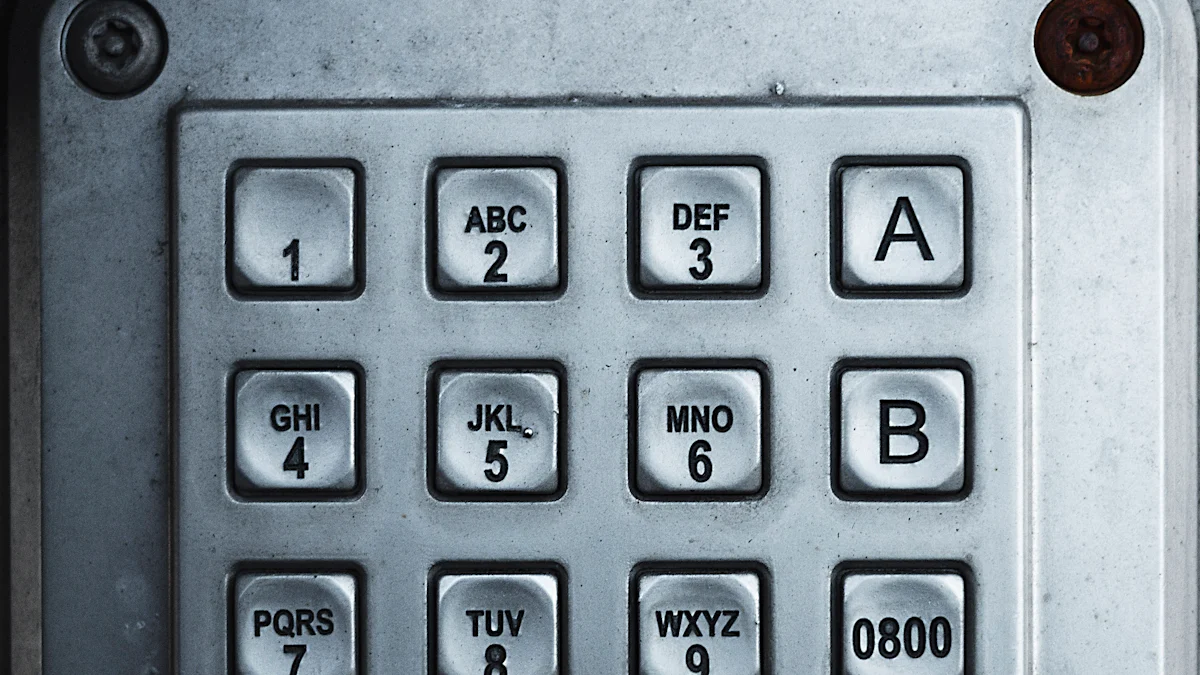

Aesthetic Appeal and Industrial Design

While functionality takes precedence, the aesthetic appeal of industrial metal keypads also matters. Modern designs balance ruggedness with sleek, professional appearances. You’ll notice that manufacturers focus on clean lines and minimalistic layouts, ensuring the keypads integrate seamlessly into industrial systems. This attention to design not only enhances usability but also reflects the sophistication of your operations.

Resistance to Environmental Factors

Industrial environments often expose keypads to harsh conditions. You need keypads that can resist moisture, dust, and temperature extremes. Stainless steel or coated metal construction provides excellent protection against corrosion, especially in marine or outdoor applications. Most industrial metal keypads feature IP65 or higher ratings, ensuring they withstand water and dust exposure.

Additional protective features include:

- Resistance to contaminants like dust and moisture.

- Metallic enclosures that shield against electromagnetic interference (EMI) and radio frequency interference (RFI).

These attributes ensure the keypads maintain performance and signal integrity, even in the most demanding environments.

Tip: When selecting a keypad, always check its IP rating and material specifications to ensure it meets your operational needs.

Ergonomics and Usability

Key Layout and Spacing

The layout and spacing of keys play a crucial role in ensuring efficient operation. Industrial metal keypads often feature well-spaced keys to minimize accidental presses, even when operators wear gloves. You’ll find that the arrangement of keys is intuitive, allowing users to quickly locate and press the desired buttons without hesitation. Manufacturers often customize layouts to suit specific applications, such as numeric-only keypads for access control or alphanumeric designs for data entry. This flexibility ensures that the keypad meets your operational requirements while maintaining ease of use.

User Comfort and Accessibility

Industrial metal keypads are designed to provide reliable performance under extreme conditions, which enhances user comfort. Their robust construction ensures consistent functionality, even in harsh environments. High customization options allow you to tailor layouts and key sizes, improving accessibility for operators with varying needs. Additionally, high Ingress Protection (IP) ratings, such as IP65, protect against dust and moisture, ensuring usability across diverse settings. These features make the keypads comfortable and accessible for all users, regardless of the challenges posed by the environment.

Note: Customizable key sizes and layouts can significantly improve accessibility for operators with specific requirements.

Adaptability to Industrial Environments

Industrial metal keypads excel in adapting to various environments. Their waterproof designs make them suitable for outdoor kiosks, ticket machines, and vehicle control systems. You can rely on them in conditions involving rain, snow, or extreme temperatures. Their resistance to vandalism and tampering ensures reliability in public access interfaces. These keypads also meet the hygiene and durability standards required in medical and laboratory equipment. Their sealed design allows for easy cleaning and disinfection, while resistance to chemicals and solvents enhances their suitability for sterile environments.

Key features include:

- Heavy-duty materials that withstand extreme temperatures and vibrations.

- Metallic enclosures that shield against electromagnetic and radio frequency interference.

- High IP ratings, such as IP65, which ensure dust-tight and water-resistant capabilities.

These attributes make industrial metal keypads a versatile solution for a wide range of industrial applications.

Functionality and Performance

Responsiveness and Key Mechanisms

Responsiveness is a critical factor in industrial metal keypads. You need keypads that respond instantly to user input, ensuring smooth operations in time-sensitive environments. Modern keypads use advanced key mechanisms, such as tactile feedback or mechanical switches, to provide a satisfying and reliable response. These mechanisms reduce the risk of missed inputs, even when operators wear gloves or work in high-pressure conditions.

Keypads designed for industrial use often feature anti-bounce technology. This ensures that each press registers accurately, eliminating errors caused by repeated signals. Additionally, the robust construction of the keys prevents wear and tear, maintaining consistent performance over time.

Tip: Look for keypads with tactile feedback and anti-bounce technology to enhance operational efficiency.

Advanced Features and Customization

Industrial metal keypads now offer a range of advanced features to meet diverse industry needs. You can choose from options like customizable backlighting, which improves visibility in low-light environments, and programmable keys tailored to specific tasks. These features enhance usability and allow you to adapt the keypad to your unique requirements.

Some keypads also include corrosion-resistant materials and high IP ratings, such as IP69K, for extreme environments. You can select key shapes, sizes, and layouts that align with your operational demands. For example, backlit legends improve visibility, while abrasion-resistant markings ensure longevity.

- Popular advanced features include:

- Waterproof and dustproof designs.

- Customizable backlighting color and intensity.

- Long-lasting key markings resistant to wear.

- Integration options like USB or RS-232 connections.

These features make industrial metal keypads versatile and reliable for applications ranging from factories to marine environments.

Integration with Industrial Systems

Seamless integration with existing systems is essential for industrial metal keypads. You need keypads that connect easily to standard interfaces like USB or RS-232. This simplifies installation and ensures compatibility with your equipment.

The robust construction of these keypads allows them to withstand extreme conditions, reducing maintenance costs. Their customizable design enables tailored layouts and features, ensuring they fit seamlessly into your processes. High IP ratings protect against dust and moisture, making them suitable for harsh environments.

Note: When selecting a keypad, prioritize compatibility with your system’s interface to streamline integration.

Industrial metal keypads combine durability, usability, and advanced functionality to meet the demands of modern industries. Key features include corrosion resistance, waterproof designs, and tactile feedback for user comfort. These keypads excel in marine environments, factories, and outdoor kiosks, where harsh conditions require robust solutions. Future designs will likely focus on enhanced durability and customization, ensuring they remain indispensable in industrial operations.

Pro Tip: Choose keypads with high IP ratings and customizable layouts for optimal performance in your specific environment.

FAQ

What is the ideal IP rating for industrial metal keypads?

You should look for IP65 or higher. This ensures protection against dust and water, making the keypad suitable for harsh industrial environments.

Can industrial metal keypads be customized for specific applications?

Yes, manufacturers offer customizable layouts, backlighting, and key sizes. These options help you tailor the keypad to meet your operational needs effectively.

How do you maintain industrial metal keypads in extreme environments?

Clean the keypad regularly using non-corrosive solutions. Ensure proper sealing to prevent moisture or dust ingress. Follow the manufacturer’s maintenance guidelines for optimal performance.

Tip: Regular maintenance extends the lifespan of your keypad and ensures consistent functionality.